What industries benefit most from using optical measurement systems?

What industries benefit most from using optical measurement systems?

Blog Article

Why Optical Dimension Solutions Are Important for Modern Production Practices

In today's affordable manufacturing landscape, you can not afford to ignore the benefits of optical dimension systems. These innovations boost precision and rate in high quality control, reducing human error that can cause costly flaws. By incorporating sophisticated laser and imaging strategies, you'll enhance procedures and boost product top quality. However just how exactly do these systems change making practices, and what effects do they hold for the future?

The Evolution of Optical Measurement Solutions in Production

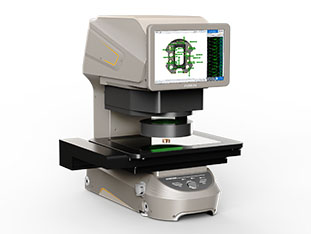

As technology rapidly developments, the advancement of optical dimension systems in manufacturing has transformed exactly how sectors assure accuracy and quality. You might've discovered that standard dimension strategies, like calipers and micrometers, typically drop brief in rate and precision. Optical systems arise as a remedy, leveraging light to capture detailed measurements rapidly.

In the past, these systems were limited, mainly utilized for particular applications. Currently, improvements in laser innovation and imaging software application enable for versatile, real-time assessments across numerous fields. You can anticipate higher precision and lowered human mistake when carrying out these systems in your processes.

In addition, the combination of automated optical evaluation tools streamlines high quality control, letting you concentrate on manufacturing effectiveness. As the demand for accuracy grows, adapting to these cutting-edge optical measurement technologies will certainly keep your procedures reliable and affordable in a hectic market.

Key Benefits of Optical Measurement Technologies

Optical dimension technologies supply a number of key benefits that can significantly boost your manufacturing processes. They give high precision and precision, enabling you to make essential modifications with confidence. This results in boosted product top quality and reduced waste, which straight affects your profits.

Furthermore, these systems are non-contact, implying you can measure fragile or relocating components without creating damage. This ability not just protects your materials yet also boosts throughput since you can determine things on the production line without disruption.

Optical systems are usually faster than standard methods, enabling you to collect information swiftly and make timely decisions. Their adaptability means they can be applied to a variety of geometries and materials, adapting quickly to your certain demands. By incorporating optical dimension technologies, you're not just staying up to date with market requirements; you're establishing them.

Applications of Optical Dimension in Numerous Industries

While many industries are increasingly turning to sophisticated measurement methods, the applications of optical measurement systems stick out as a result of their one-of-a-kind capacities. In auto production, you'll locate these systems aiding to assure specific placement and surface area top quality in parts. In aerospace, they're crucial for evaluating intricate geometries and assuring the safety and security of essential components.

In electronic devices, optical measurement aids in the accurate positioning of microchips on circuit boards, boosting total effectiveness. The medical device industry additionally advantages, as these systems enable for the precise measurement of detailed parts, guaranteeing they meet stringent governing requirements.

Optical measurement systems are also made use of in fabrics, where they evaluate fabric patterns and blemishes, boosting high quality. With their flexibility, these systems are revolutionizing just how different industries come close to measurement, ultimately driving technology and effectiveness in manufacturing processes.

Enhancing Quality Assurance With Optical Measurement

When it pertains to high quality control, precision dimension techniques can make all the distinction in your manufacturing procedure. By executing optical dimension systems, you can accomplish real-time quality control that keeps your items consistent and trusted. This not just boosts your overall production efficiency however likewise boosts client fulfillment.

Precision Measurement Techniques

In today's competitive manufacturing landscape, applying precision dimension techniques can considerably enhance quality assurance procedures. By utilizing innovative optical dimension systems, you can achieve greater precision and repeatability in your measurements. These methods permit you to spot also the least variations in product measurements, making certain that every component satisfies rigid requirements.

Using tools like laser scanners and optical comparators, you can swiftly analyze the quality of your products, significantly minimizing the threat of defects. These systems supply real-time information, allowing you to readjust procedures immediately, thereby reducing waste.

Incorporating these precision measurement techniques not just boosts item top quality yet additionally enhances consumer contentment and self-confidence in your brand name. Welcome these technologies to keep an affordable side in your manufacturing operations.

Real-Time Quality Control

As makers venture for quality, real-time top quality assurance comes to be crucial for preserving high standards. Optical dimension systems play an important role in this procedure, allowing you to check product top quality constantly. By integrating these systems right into your workflow, you can identify variances from specifications nearly immediately, lowering the possibilities of defects reaching the marketplace. This instant responses loop allows you to make quick modifications, boosting production performance and minimizing waste. You'll likewise cultivate a culture of top quality throughout your organization, as workers can see the straight impact of their work with last products. Eventually, welcoming real-time quality guarantee with optical dimension systems not only increases your result but likewise enhances consumer count on your brand name.

Reducing Waste and Improving Efficiency With Optical Systems

When you implement optical measurement systems, you'll see a significant reduction in production mistakes. These systems simplify quality control procedures, making it less complicated to recognize and deal with concerns promptly. Because of this, you not just lower waste however also enhance overall performance in your production procedures.

Minimizing Manufacturing Errors

To minimize production errors successfully, manufacturers increasingly depend on optical dimension systems that boost accuracy and decrease waste. By utilizing exact dimensions, you can guarantee that every component satisfies specs, which substantially decreases the risk of defects. As you accept optical measurement systems, you'll observe a significant decline in rework and scrap prices, inevitably leading to more efficient manufacturing practices and improved bottom-line results.

Improving High Quality Control

By embracing optical measurement systems, you're not only reducing production errors yet additionally simplifying quality assurance. These systems give real-time responses, permitting you to discover issues prior to they escalate. As opposed to relying upon manual evaluations, which can be taxing and vulnerable to human error, you can automate the procedure. This rates up manufacturing and assurances consistency across sets. With specific dimensions, you can determine variations in products or procedures promptly, lowering waste and boosting general efficiency. In addition, incorporating optical systems assists you maintain conformity with market standards, offering you an affordable edge. Ultimately, spending in optical measurement technology boosts your high quality control, leading to far better products and satisfied consumers.

Integrating Optical Dimension Systems Into Existing Procedures

Next, choose the right optical measurement technology that aligns with your production demands. Consider factors like the dimension of the parts, called for accuracy, and assimilation abilities with existing devices. Training your personnel on the new technology is essential; they need to really feel certain utilizing it to maximize its benefits.

Finally, monitor the assimilation procedure carefully. Collect data on efficiency renovations and determine any challenges early on. This aggressive technique assurances not only a smooth change however also a lasting effect on your production efficiency and item high quality.

The Future of Optical Measurement in Production

As you welcome optical measurement systems in your production processes, it's crucial to look in advance and think about just how these technologies will certainly advance. Future improvements assure enhanced precision and rate, enabling real-time comments that can dramatically minimize manufacturing mistakes (optical measurement system).

In addition, miniaturization of optical sensors will make them a lot more functional, fitting into tighter areas and different applications. The surge of automation optical measurement systems will also improve their capacities, as automated systems will certainly utilize these measurements to enhance manufacturing circulations flawlessly.

As you adapt to these changes, staying notified regarding arising modern technologies will certainly be essential. By buying advanced optical measurement services, you'll position your manufacturing operations for long-lasting success and effectiveness. Accept the future; it's brilliant for those that introduce!

Often Asked Concerns

Exactly How Do Optical Measurement Solutions Compare to Conventional Measurement Methods?

Optical measurement systems offer higher precision, performance, and rate contrasted to standard techniques - optical measurement system. You'll find they reduce human mistake and improve data collection, making your measurements more trusted and boosting general productivity in your processes

What Are the First Expenses of Executing Optical Dimension Equipments?

You'll discover the initial prices of carrying out optical measurement systems can be substantial, commonly including equipment training, software, and acquisition. However, these financial investments usually lead to better efficiency and precision in the long run.

Exist Particular Training Needs for Using Optical Dimension Systems?

Yes, you'll need details training to utilize optical dimension systems effectively. Acquainting on your own with the devices, dimension, and software techniques is necessary. Suppliers frequently supply training programs to assure you're competent and confident in utilizing these systems.

Can Optical Dimension Equipments Be Customized for Distinct Manufacturing Requirements?

Yes, you can tailor optical dimension systems to fulfill your specific manufacturing needs. By changing specifications and integrating one-of-a-kind attributes, these systems can enhance effectiveness, accuracy, and flexibility, ensuring they align perfectly with your production needs.

What Upkeep Is Needed for Optical Dimension Solutions?

You'll need to frequently clean up the optics, calibrate the system, and look for software updates. Monitoring efficiency and resolving any type of wear or tear immediately ensures your optical measurement systems operate properly and dependably in time.

Conclusion

In today's fast-paced production world, embracing optical dimension systems is crucial for staying affordable. These modern technologies not only enhance accuracy and speed but additionally enhance quality control and lower waste. By incorporating these advanced remedies right into your processes, you'll cultivate a culture of reliability and consumer fulfillment. As you want to the future, purchasing optical measurement will certainly ensure your operations stay efficient and certified, positioning your organization for continued success in the ever-evolving landscape.

As technology quickly breakthroughs, the development of optical dimension systems in production has changed just how industries assure accuracy and quality.While lots of industries are progressively transforming to innovative measurement methods, the applications of optical dimension systems stand out due to their unique abilities. By using innovative optical measurement systems, you can accomplish greater precision and repeatability in your dimensions. Optical measurement systems play an important duty in this procedure, allowing you to keep track of product top quality continually. How Do Optical Measurement Solutions Compare to Standard Dimension Approaches?

Report this page